Finishing that lasts

Spray finishing, powder coating, and protective coatings. We control every step so the final product looks right and holds up.

Finishing processes and applications

Spray finishing creates smooth, uniform surfaces on fabricated components. Powder coating provides durable protection for exterior metalwork. Clear protective coatings preserve natural wood grain. Pantone-matched brand colors maintain consistency across signage and displays. UV-resistant finishes stop colors fading outdoors.

Each process suits different materials and environments. Metal signage for building exteriors needs powder coating that resists weathering. Retail displays need finishes that handle constant customer contact. Architectural panels need UV stability. Food service components need food-safe coatings. We match finishing processes to actual use conditions.

Surface preparation determines finish quality

Shot-blast cleaning removes rust and contaminants from metal. Degreasing strips oils that prevent coating adhesion. Sanding prepares wood surfaces for clear finishes. Primer coats bond topcoats to substrates and prevent corrosion. Each material needs specific preparation - shortcuts cause peeling, blistering, or early failure.

Most fabricators outsource finishing because specialist equipment costs money. That creates delays when components ship between facilities. Colors need adjustment? Wait for the next batch. Rush job? Join the queue. We finish on-site with our own spray booth and powder coating systems, so fabrication and finishing happen in sequence without coordination delays.

50 years finishing everything. We know what lasts.

Spray booth, powder coating, custom color matching—all on-site. No outsourcing means no delays and full control over quality.

Why finishing matters

Finish On-Site

We control surface prep, color matching, cure times, and quality. No outsourcing means no delays waiting on third parties.

Built to Last

Proper surface prep and professional-grade coatings mean finishes that hold up to real-world use and weathering.

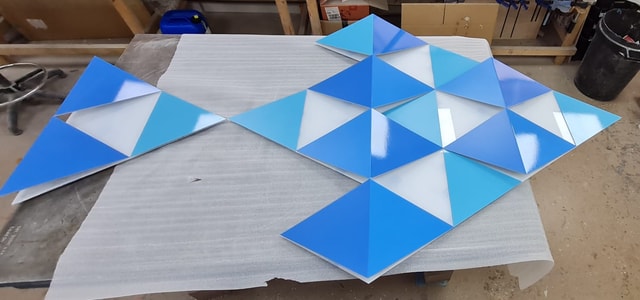

Color Matching

Pantone references, ICC profiles, sample proofs—we match your brand colors accurately across all components.

What we finish

Signage, displays, retail units, architectural components. If it needs a finish, we handle it.

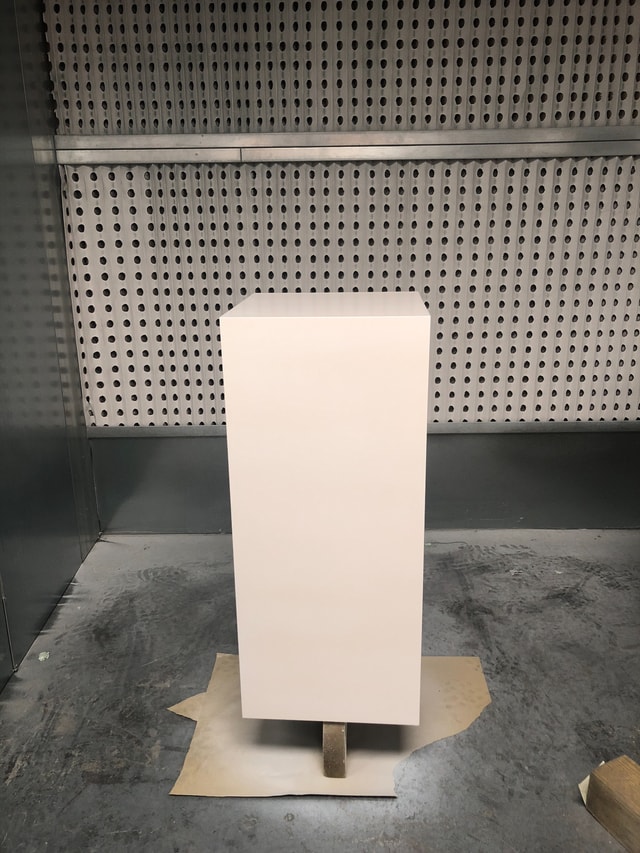

Spray Finishing

Smooth, uniform finishes with gloss, matte, or custom options

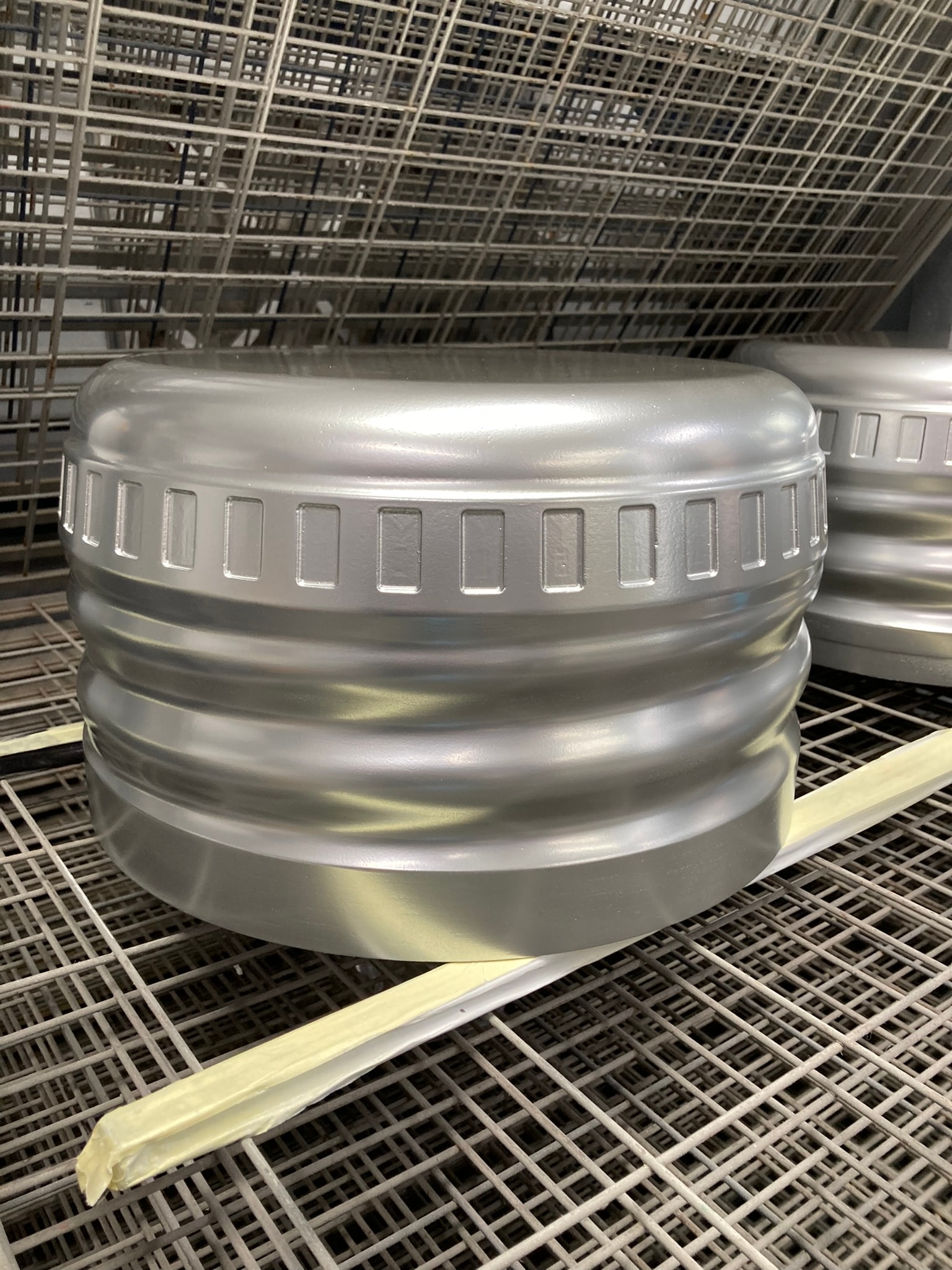

Powder Coating

Durable, industrial-grade protective finish

Protective Coatings

Weather-resistant finishes for exterior applications

Custom Colors

Pantone matching and brand color development

Clear Finishes

Protective coating for wood and natural materials

Surface Prep

Shot-blast cleaning and proper preparation

How we handle finishing

Proper surface prep, material-specific coatings, quality inspection.

Surface Prep

Shot-blast cleaning, defect correction, surface inspection. Proper prep is what makes finishes last.

Primer

Base coat for adhesion and corrosion protection. Material-specific primers for optimal results.

Finish Coats

Multiple spray layers with color matching and thickness verification. Uniform coverage matters.

Quality Check

Visual inspection, adhesion testing, coverage verification. Issues get caught before it leaves the facility.

Why work with us?

Half a century finishing everything from retail displays to architectural metalwork.

A Bad Finish Ruins Everything Before It

You can fabricate the most precise component in the world, but if the finish is uneven, peeling, or the wrong color, none of that matters. Most fabricators outsource finishing, which means delays, quality issues, and no control over the final result. We finish everything on-site with our spray booth and powder coating systems. When something needs a touch-up or rush finish, we handle it immediately.

50 Years of Production Finishing

Signage, displays,

Control the Entire Process

Materials and Environments Matter

Exterior signage needs UV-resistant coatings. High-traffic retail displays need durable finishes. Architectural elements need specific surface treatments. We select coatings based on your application and longevity requirements, not just what looks nice.

Built in Kent. Finished in-house.

Our spray booth and powder coating systems handle everything from retail displays to large fabrications.

More finishing work

A selection of projects from our spray booth and powder coating systems.

Related Services

Enhance your project with our complementary services

The equipment behind it

Industrial machines and precision tools. All in-house.

Post-Production & Finishing

Equipment for finishing, laminating, and post-production work

Need professional finishing?

Let us handle your finishing requirements. Get in touch to discuss coatings, colors, and timelines.